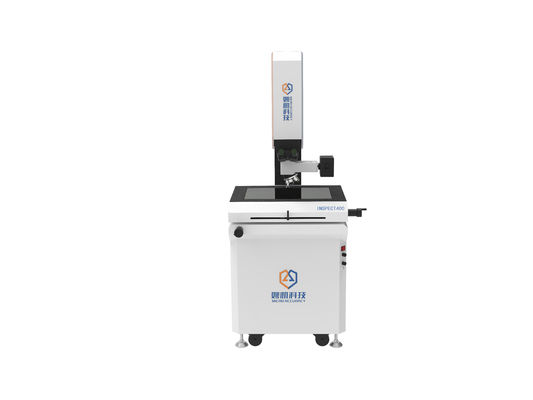

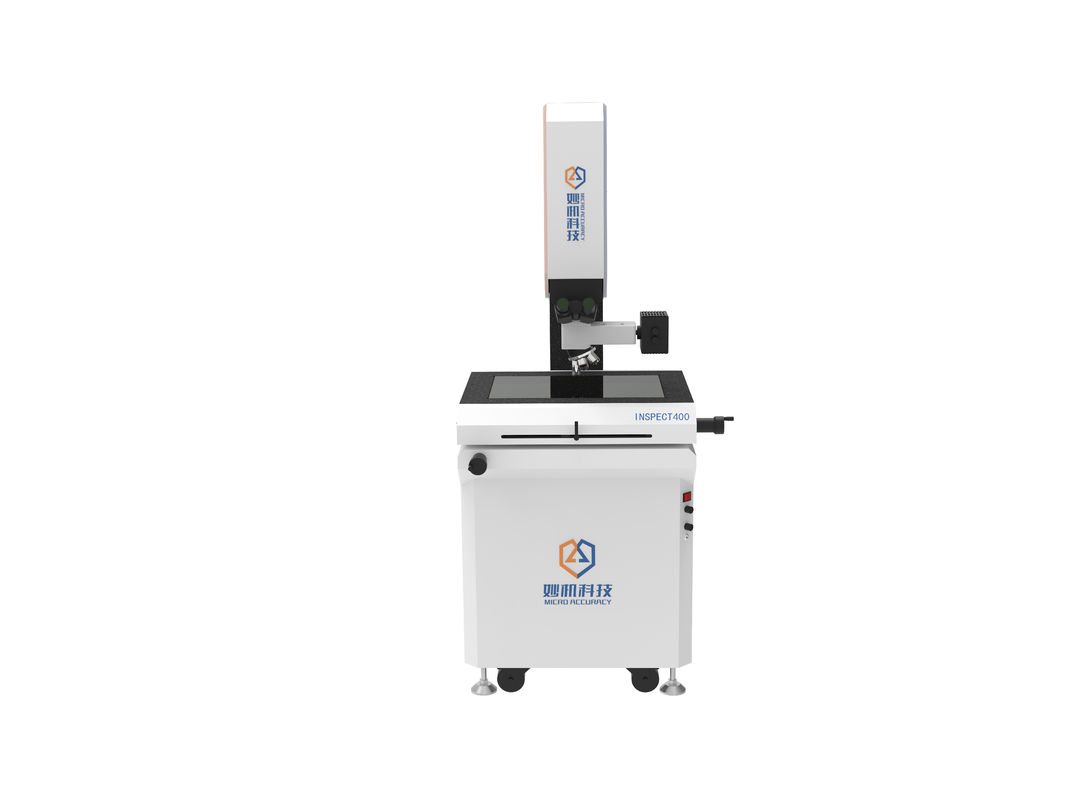

INSPECT400 Measuring Metallurgical Microscope for Wafer inspect

Product Details:

| Place of Origin: | China |

| Brand Name: | MICRO ACCURACY |

| Certification: | CE |

| Model Number: | INSPECT400 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Piece |

|---|---|

| Price: | negotiation |

| Delivery Time: | 14 WORKNG DAYS |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 50, 000PCS/Year |

|

Detail Information |

|||

| Model NO.: | INSPECT400 | Accuracy: | (2.5+L/150)Micron |

|---|---|---|---|

| Z Axis Driving System: | Servo Motor Control | Resolution Of X/Y/Z-Axis: | 0.001 Mm |

| Software: | ZoomView | Eyepiece Magnification: | 50*500X |

| Trademark: | Micro Accuracy | Transport Package: | Standard Exporting Package |

| Specification: | SGS, CE | Origin: | Guangdong |

| HS Code: | 9031809090 | Port: | Shenzhen, China |

| High Light: | 0.001mm CNC Video Measuring System,190X CNC Video Measuring System,Benchtop optical measuring machine |

||

Product Description

INSPECT400 Measuring Metallurgical Microscope for Wafer inspect

INSPECT400 Measuring Metallurgical Microscope for Wafer inspect

Usage

INSPECT series measuring metallurgical microscope are widely used in semiconductor packages, solder pads, loop height, FPD panels (LCM), wafer level CSPS and so on.

Features

■ High-precision marble base, table and column to ensure high stability and rigidity

■ Marble table design, with precision V-shaped cross rail, ensure long-term use without deform, effectively guarantee high mechanical precision

■ High-quality optical system and high-resolution CCD ensure sharp image edges

■ Three-ring and eight-zone LED ring surface cold light source and contour light source, avoid the deformation of precision parts caused by the heat from light

■ Optional Nikon tilting trinocular tube + quintuple nosepiece

■ Independent research and development of image measuring software, powerful and easy to operate

Technical data

| Model | INSPECT300 | INSPECT400 | INSPECT500 | ||||

| X,Y axis travel(mm) | 300*200 | 400*300 | 500*400 | ||||

| Stage glass size(mm) | 357*257 | 457*357 | 557*457 | ||||

| Z axis travel(mm) | 100 | ||||||

| X,Y,Z axis resolution (μm) | 1 | ||||||

| Length unit | Linear scale | ||||||

| Measuring accuracy (μm) | 2.5+L/150, L=measuring length (mm) | ||||||

| Operation mode(X, Y) | Manual | ||||||

| Operation mode(Z) | CNC | ||||||

| Camera | High resolution CCD camera | ||||||

| Quintuple nosepiece | 5X | 10X | 20X | 50X | |||

| Eyepiece | WF10X | ||||||

| Measuring software | 2D measuring software | ||||||

| Illumination | Transmitted | Epi-illumination system | |||||

| Contour | LED parallel contour light | ||||||

| Power supply | AC100~240V 50/60Hz | ||||||

Features of Infinity plan achromatic bright field objective

PL L5X/0.12 (Work distance):26.1 mm

PL L10X/0.25 (Work distance):20.2 mm

PL L20X/0.40 (Work distance):8.80 mm

PL L50X/0.70 (Work distance):3.68 mm

6V/30W halogen and brightness enable control( Reflected light)

![]()

![]()